However, when a floating roof is landed-i.e., the roof is resting on the tank bottom-the space under the floating roof can be thought of as similar to the vapor space of a fixed-roof tank.

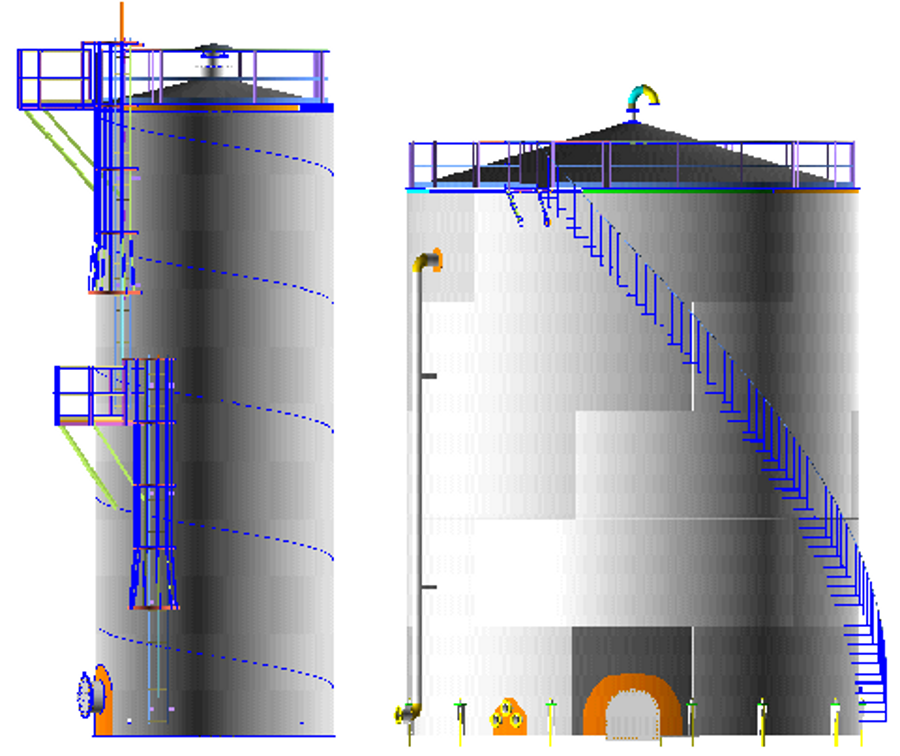

Figures 1, 2 and 3 illustrate the three types of roofs.Īs implied above, the space above a floating roof is either open (external floating roof) or covered with a fixed roof that is vented to the atmosphere (internal floating roof). Tanks with only a fixed roof are referred to as just that: fixed-roof tanks. So, floating-roof tanks are said to have either external or internal floating roofs. Do not be confused by the fact that some tanks with floating roofs also have fixed roofs in other words, the floating roof is internal. The venting requirements for API 650 tanks may be segregated into rules for tanks with floating roofs and tanks with fixed roofs. The first step in assessing venting requirements is to identify the kind of tank involved and whether it has a floating roof. The next sections will provide some of these basics, after which the standards for certain types of tanks and venting will be summarized. To understand the requirements, you need to understand some basic features of tanks and the different types of, or reasons for, venting. Yet, it is incumbent upon the tank purchaser to understand venting sufficiently to specify the intended service conditions and venting requirements. In fact, API 2000 acknowledges that API 650 is not as definitive as it might be in presenting venting requirements. In some cases, venting requirements are not readily apparent from the standards. This article should help clarify some of the “unwritten,” but important, issues for anyone working with tank venting.ĪPI 650 specifies venting requirements for certain scenarios and, for other scenarios, refers to API 2000.

For example, storing liquids that are subject to rapid chemical reaction within the liquid or ignition of combustible vapors above the liquid are not within the standards’ scope. Other factors to consider are not so easy.

Some basic factors that should always be considered are the tank’s design pressure, the stored product’s flash point, and whether or not the tank has an internal floating roof. This article covers venting standards for tanks designed to API 650. As this article will explain, a simple device called a pressure-vacuum (PV) vent valve was invented to reduce the frequency and volume of vapor releases and prevent flames outside a tank from propagating to the vapor space inside.īecause of the importance of proper venting, API has published standards for determining whether and how aboveground tanks should be vented. The loss of product through such emissions also presented hazards of fire from outside ignition sources. Liquids of relatively high volatility, such as motor fuels, degraded by “weathering” to the point that the more volatile components simply got blown away through the open vents. In the early days of oil storage, tanks were simply vented to the atmosphere through open vents. How does proper venting accomplish these objectives? Proper venting of tanks and vessels is essential to conserve product, reduce emissions and minimize hazards to people and equipment. Then use the clients' specified values in your API 650 calculations.Venting of aboveground storage tanks is one of the most difficult aspects of tank engineering to understand and apply. If you're interested in reading further to compare with other storage tank standards, you could look at BS EN 14015:2004 secion 5, table 3, from which you could perhaps take a view as to the minimum pressure and vacuum ratings that could be considered as reasonable in discussions with your client. API 650: Addendum F is useful, the decision tree Fig F-1. G indicates the maximum is 2.5 PSI(g) for an "API Atomspheric Pressure" tank. Please also refer to the following : API 650 paragraphs 3.2.1 g and h are relevent. See Appendix L item 9 = "Design Pressure" i.e., the client must specify this. I would recommend clarification of the required design presure and vacuum rating from the client. See API 2000 for venting requirements.Įxport rates and tank vacuum ratings are important too, since inadequate provision will cause the tank to be sucked in. You must consider an internal design pressure because of the internal pressure created in a fixed roof tank during product imports.

0 kommentar(er)

0 kommentar(er)